Shantui SDX5312GJBE1 Camión mezclador de concreto

Características del producto

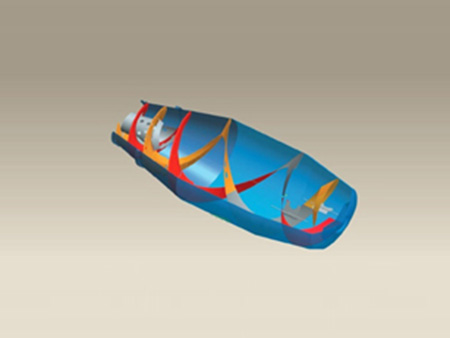

Mixing drum and blade

● A mode of combining a cylindrical segment Archimedes spiral and an oblique cone-circle logarithmic spiral is adopted.,And that main blade are designed into unequal helical angle according to the trend of a helical line on different sections of the cylinder body.、Pitch、Lead angle and lead angle,And the dead angle at the joint between the blade and the cylinder wall and the variable pitch stirring blade are eliminated.。

● Large space for loading and mixing,And ensure the mixing quality of concrete,Progress can be achieved、And that discharge speed is high,The uniformity of concrete is good,And that net yield is high,And that material are not accumulated。

● The cylinder is made of high wear-resistant material.B520JJ,And that service life is long。

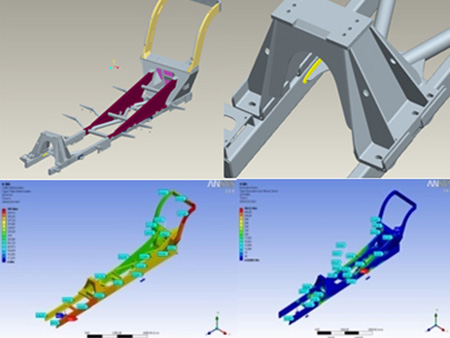

Frame

● A finite element analysis was performed,Flexible connection is adopted,Reduce the impact。

● Split front desk,Eliminate stress concentration,The overall rigidity is enhanced。

● The frame material is 16MnMaterial。

Water wash system

● Air pressure water supply is adopted,Wate tank with large capacity、Add water and exhaust air quickly。

● Equipped with various valves、Instrument,And that seal performance is good,Able to ensure driving and cleaning needs。

● Pipes can be separately connected to the mixing drum、In and out of the chute,Equipped with high-pressure water gun,It can clean the whole vehicle in all directions.,Convenient、Quick Jie。

Manipulation mode

● Flexible shaft type and mechanical control type are adopted for control,It mainly controls the positive and negative rotation of the mixing drum and the rotation speed of the mixing drum.。

● Flexible shaft control:An operating handle and a flexible shaft.,The rotation direction of the mixing drum can be controlled、Regulate engine throttle and have locking function,The handle is compact、Beauty,Operation is easier、Flexible、Reliable。

● Mechanical manipulation:Durable、Applicable to cab control and vehicle left and right operation、Flexible。

Hydraulic system

● Hydraulic pump,Hydraulic Motor,All reducers are of international famous brands.,The performance is safe and reliable。

● The flywheel shell of the chassis engine is connected with the hydraulic pump through the transmission shaft to generate pressure to drive the motor to rotate.,And then that mix drum is driven to rotate through the speed reduction of the speed reducer.。

Chassis manufacturer

● The second class chassis of Sinotruk is refitted.,It has good dynamic performance、Mobility、Comfortable、Economy and reliability in use。

Parámetros del producto

Performance parameters |

SDX5312GJBE1 |

Curb weight(kg) |

15260 |

Effective volume(m³) |

12 |

Mixing drum performance |

|

Feed rate(m³/min) |

5 |

Discharge speed(m³/min) |

2 |

Discharge residue rate |

<0.6% |

Range of slumpmm |

40-210 |

Overall dimensions of the complete machine |

|

Long(mm) |

10060 |

Wide(mm) |

2500 |

High(mm) |

3950 |

Hydraulic system |

|

Hydraulic pump、Hydraulic Motor、Reducer |

International famous brand |

Water supply type |

|

Water supply mode |

Air pressure water supply |

Water tank capacity |

500L,Can be specially customized |

Vehicle Chassis |

|

Drive form |

8×4 |

Brand |

Sinotruk |

Maximum speed(km/h) |

82 |

Engine model |

MC07.34-50 |

Type of fuel |

Diesel |

Emission standards |

Guowu |

Number of tires |

12 |

Tyre size |

11.00R20 18PR |